A New Era of Transparency in Product Lifecycles

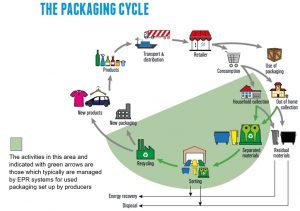

The way we view product responsibility is shifting. No longer is it enough to think about disposal at the end of a product’s life. Instead, industries and regulators are embracing full lifecycle thinking—where transparency, traceability, and accountability are built into every stage of a product’s existence. This change is being driven by the dual forces of Extended Producer Responsibility (EPR) policies and emerging digital technologies like product passports, which offer a window into the materials and processes behind each product.

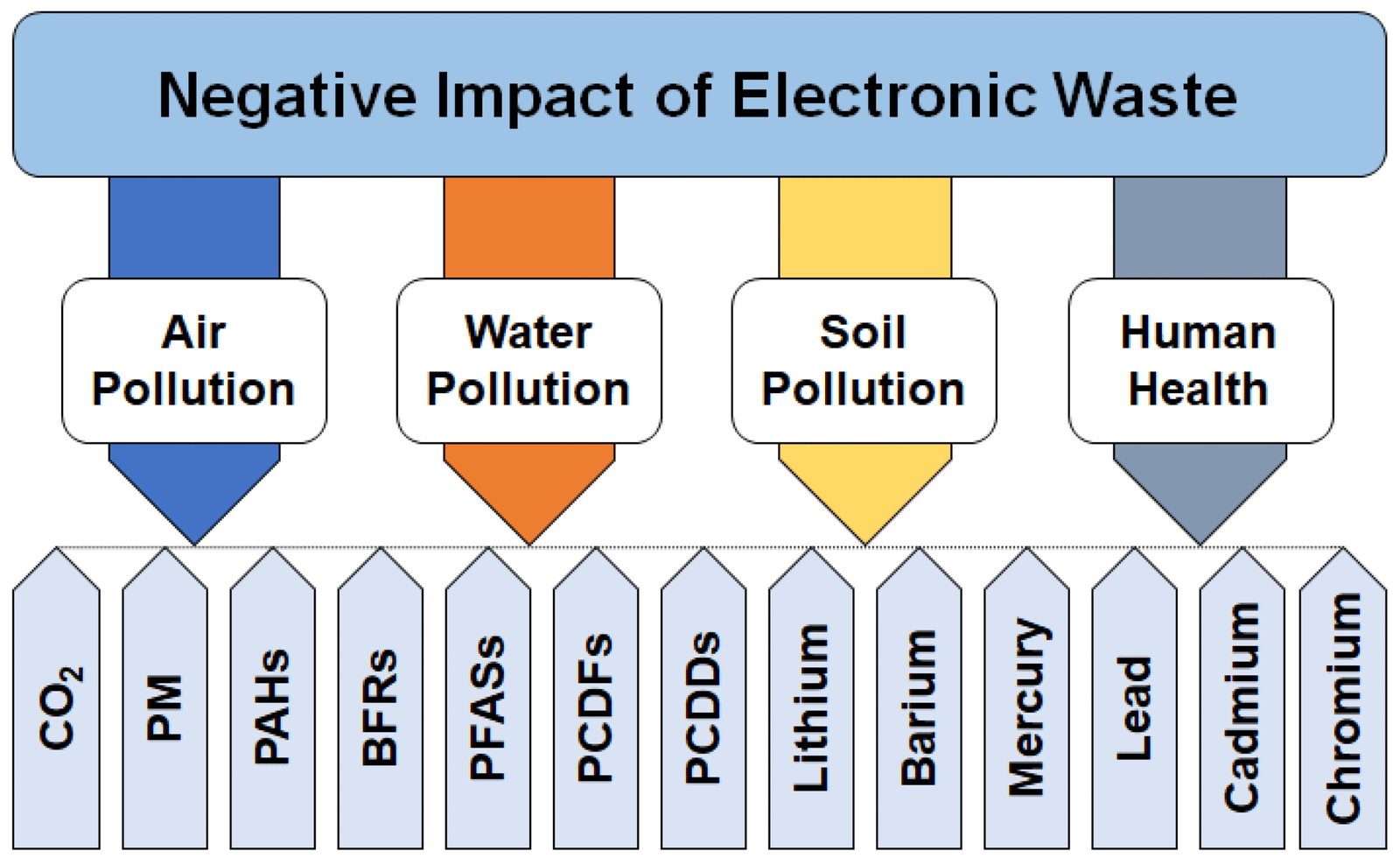

Product passports are digital records that contain essential information about a product’s origin, composition, repairability, reuse potential, and recyclability. From raw materials to final recycling or safe disposal, these passports provide a comprehensive timeline of a product’s environmental footprint. For EPR systems, which hold producers responsible for managing post-consumer waste, this granular level of detail is transformative. It equips producers with the data needed to prove compliance, optimize resource use, and design for circularity.

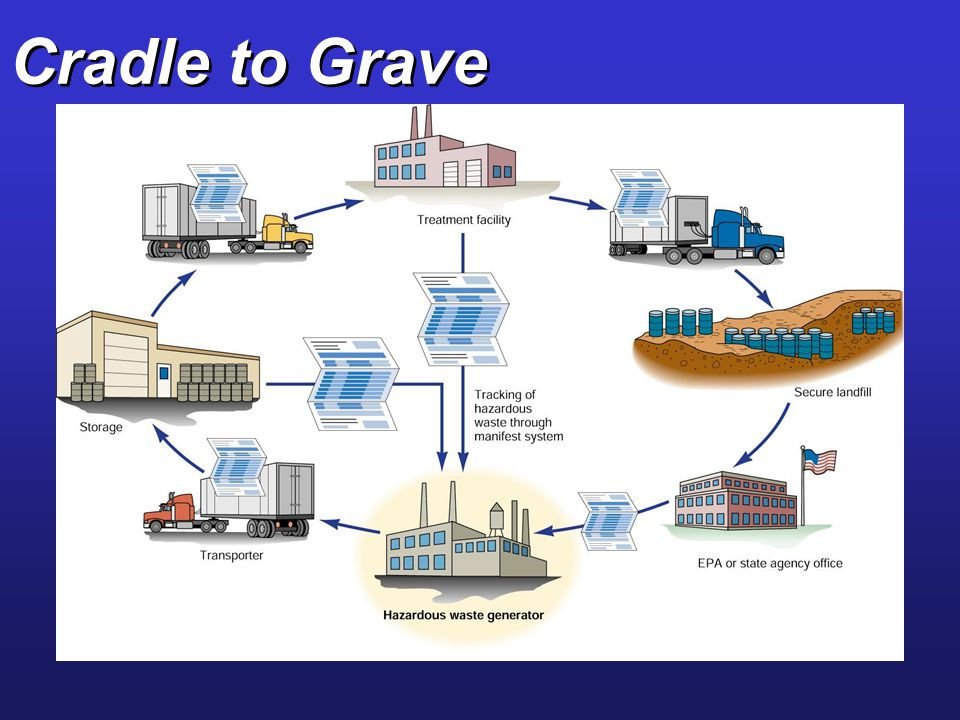

In traditional EPR models, producers often struggle with incomplete data about where their products end up, how they’re handled, or what materials are actually being recovered. Product passports aim to close these data gaps by creating a standardized and accessible source of truth. By digitizing lifecycle data and linking it to individual products or batches, regulators and stakeholders can track environmental performance with far greater accuracy.

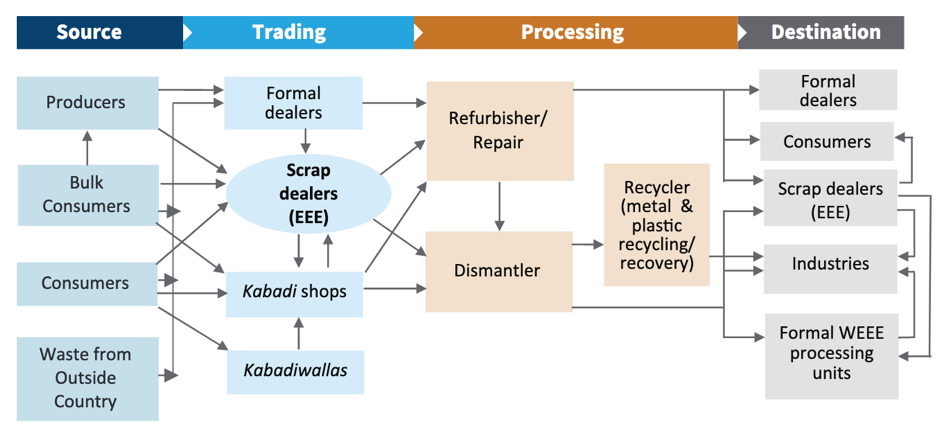

This approach has wide-reaching implications beyond just compliance. For manufacturers, it creates opportunities to improve supply chain transparency, reduce material waste, and meet growing consumer demands for sustainability. For recyclers and refurbishers, the information in product passports helps them safely dismantle and reuse components more efficiently. And for policymakers, it means more reliable reporting, targeted interventions, and better enforcement of circular economy goals.

- Improved traceability of materials and components

- More accurate reporting for EPR obligations

- Support for eco-design and circular business models

- Enhanced consumer trust through product transparency

- Stronger coordination between producers, recyclers, and regulators

As governments push for deeper accountability in waste management and sustainability, tools like product passports will play a key role in elevating EPR from a regulatory requirement to a strategic advantage. We are entering a new era—one where transparency isn’t optional, but essential to a functioning circular economy.

As Extended Producer Responsibility (EPR) continues to evolve, a new concept is taking center stage—product passports. These digital tools promise to revolutionize how we track, manage, and recycle materials across a product’s life, from raw material extraction to end-of-life disposal. For industries navigating EPR obligations, product passports offer a practical way to improve traceability, demonstrate compliance, and accelerate the shift toward a truly circular economy.

What Are Product Passports and Why Are They Emerging Now?

Product passports are digital documents or platforms that collect and store detailed information about a product’s entire lifecycle—from material sourcing and manufacturing to repair, reuse, and end-of-life processing. These passports are designed to travel with the product or remain accessible through a digital link or embedded identifier, making it easier for stakeholders across the supply chain to access vital information. In the context of Extended Producer Responsibility (EPR), they are fast becoming critical tools to enhance traceability, accountability, and environmental performance.

The growing interest in product passports is driven by a confluence of global trends. First, there is increasing pressure on industries to transition from linear to circular models of production and consumption. Second, regulations around EPR and sustainable product design are tightening, demanding more transparency about what goes into a product and how it will be handled after use. Third, consumers are demanding more visibility into the environmental impact of the goods they purchase, fueling demand for accessible product information.

What sets product passports apart from traditional labeling or documentation is their dynamic, digital nature. These tools can integrate a wide array of data, including material composition, carbon footprint, repair instructions, recycling pathways, and even social compliance indicators. Because the data can be updated throughout the product’s life, it provides real-time relevance for stakeholders—especially producers, recyclers, and regulators working within EPR systems.

- Detailed material and component breakdowns

- Lifecycle environmental impact data

- Repair and refurbishment guidelines

- Information on recyclability and disposal methods

- Supply chain and sourcing certifications

The European Union’s push for a Digital Product Passport (DPP) under the Ecodesign for Sustainable Products Regulation has brought the concept into the global spotlight. Similar initiatives are being piloted in various countries and industries, from electronics and textiles to automotive and batteries. As these pilots mature, product passports are expected to become a regulatory norm rather than a voluntary feature—particularly in sectors with significant environmental footprints.

For businesses, adopting product passports is no longer a futuristic idea—it’s a timely move to stay ahead of evolving compliance demands, improve supply chain visibility, and meet the expectations of environmentally conscious consumers. For EPR frameworks, these tools offer a practical path to accurate reporting, better waste recovery, and deeper lifecycle accountability.

A product passport is essentially a digital record that stores comprehensive information about a product’s components, materials, sourcing, and environmental impact. It travels with the product throughout its life, offering a transparent record of origin, repairability, reuse, and recyclability. As the push for sustainable production grows, regulatory bodies, including those implementing EPR policies, are increasingly seeing product passports as tools for monitoring compliance and closing information gaps.

How Digital Traceability Supports EPR Compliance

Digital traceability is emerging as a cornerstone of effective EPR compliance, and product passports offer a powerful way to implement it. By capturing detailed data about a product’s material inputs, manufacturing processes, usage, and end-of-life pathways, these passports enable producers to track and document their responsibilities throughout the lifecycle. This is especially valuable in complex supply chains, where data is often fragmented or incomplete.

With digital traceability, producers can demonstrate how much of their product has been collected, reused, recycled, or disposed of in accordance with EPR mandates. For example, a company subject to plastic waste EPR rules can use a product passport to show the exact polymer types used, their recyclability, and how the product was processed after consumption. This level of transparency not only supports regulatory reporting but also reduces the risk of non-compliance and associated penalties.

Moreover, digital records minimize reliance on manual documentation and third-party declarations, which are often prone to error or inconsistency. By integrating real-time data streams into a centralized, verifiable system, product passports create an audit-friendly environment. This helps both businesses and regulators move from reactive reporting to proactive environmental stewardship—streamlining compliance while enabling more strategic decision-making around resource use and product design.

Digital traceability through product passports allows producers to monitor where materials originate and how they’re processed throughout the value chain. This granular visibility helps businesses meet specific recycling and take-back targets, document safe disposal, and prove regulatory adherence. It also enhances data accuracy in EPR reporting by eliminating guesswork or third-party dependency, especially in complex, globalized supply chains.

The Role of Standards and Interoperability

For product passports to function at scale, they must adhere to common data standards and be interoperable across platforms. Organizations like the European Commission and GS1 are already working to create frameworks for consistent data labeling. These efforts are critical in enabling seamless data exchange between manufacturers, recyclers, and regulators—especially for cross-border EPR compliance.

Unlocking Circular Economy Benefits Through Material Intelligence

The transition to a circular economy relies on more than just better recycling infrastructure—it depends on smart, actionable information about the materials that flow through our economy. This is where material intelligence becomes a game-changer. Product passports, by embedding detailed information about materials into digital formats, unlock the potential for smarter decisions across the product lifecycle. They help producers, recyclers, and regulators understand not just what a product is made of, but how those materials can be recovered and reused efficiently.

Material intelligence refers to the data-driven understanding of a product’s composition, environmental impact, and potential for circular use. With this intelligence embedded in a product passport, stakeholders can plan for reuse, refurbishment, or recycling before the product even enters the market. For example, if a product contains rare earth metals, its passport can highlight recovery opportunities at the end-of-life stage, enabling recyclers to handle it with greater precision and value retention.

This proactive approach offers substantial benefits. Producers can optimize design for disassembly and durability. Waste handlers can sort products more accurately and recover high-value materials. And policymakers gain better visibility into material flows, enabling more effective regulation and intervention. As EPR regulations demand increasingly detailed reporting and recovery performance, material intelligence becomes a strategic asset rather than just a compliance tool.

- Improved material recovery rates and reduced landfill reliance

- Incentives for eco-design and modular manufacturing

- More efficient sorting and dismantling processes

- Better valuation of secondary raw materials

- Enhanced product longevity through repair and reuse insights

In a world where natural resources are under pressure and regulatory scrutiny is rising, the ability to trace and act on material data is critical. Product passports turn passive products into active sources of insight, guiding each stakeholder toward decisions that support circularity. When integrated into EPR systems, they not only fulfill reporting needs but also drive innovation, cost savings, and long-term sustainability.

When integrated with EPR systems, product passports serve a dual purpose: facilitating compliance and enabling smarter material recovery. The detailed insights they provide into material content can drive circularity by guiding reuse strategies, informing eco-design, and enabling efficient dismantling and sorting during recycling. This benefits both businesses and the environment.

Applications Across High-Waste Industries

Sectors such as electronics, automotive, batteries, and textiles are already testing product passport models. In electronics, for instance, a passport can detail the presence of hazardous substances or rare earth elements—data crucial for safe dismantling and recovery. Automakers are using similar tools to track recyclable components, helping them meet EPR targets and reduce production waste.

- Product passports provide data for smarter material recovery

- They encourage sustainable product design and reuse

- Industries gain a competitive edge through transparency and trust

Bridging the Gaps: Policy, Technology, and Industry Alignment

While product passports have immense potential to revolutionize EPR and support circular economy goals, their success depends on alignment across three key areas: policy, technology, and industry adoption. Without coordinated efforts among these pillars, the promise of traceable, sustainable materials could remain unrealized. Achieving this alignment requires regulatory clarity, interoperable digital infrastructure, and strong industry participation.

Policymakers play a central role in creating the regulatory framework that mandates or incentivizes the use of product passports. This includes defining the minimum data sets, setting rules for data access and ownership, and ensuring that systems support cross-border trade. The European Union has taken a lead by integrating digital product passports into its Ecodesign for Sustainable Products Regulation, setting a precedent that other countries, including India, are beginning to observe and adapt. Without clear and enforceable policies, however, the private sector may lack the motivation to invest in the required systems.

Equally important is the role of technology. For product passports to function effectively, they must be built on open standards and interoperable platforms. Blockchain, QR codes, cloud databases, and Internet of Things (IoT) sensors are among the tools being explored to store and transfer passport data reliably. But these technologies must be accessible, secure, and scalable—especially for small and medium enterprises (SMEs), which form the backbone of many industries.

Lastly, industries need to see the value in adopting product passports beyond mere compliance. When implemented well, these tools can support supply chain transparency, risk reduction, and new business models such as product-as-a-service or take-back schemes. Collaboration among manufacturers, recyclers, logistics providers, and digital solution companies is crucial to create systems that are both practical and economically viable.

- Policies must clearly define data requirements and roles across the value chain

- Technology platforms should be open, secure, and interoperable

- Industry stakeholders must be actively involved in shaping implementation standards

- Support mechanisms are needed for SMEs to adopt digital traceability tools

- Global harmonization of standards can reduce friction in cross-border compliance

Bridging these gaps is not a one-time effort—it requires continuous dialogue between regulators, tech providers, and industry leaders. Pilot projects, multi-stakeholder partnerships, and regulatory sandboxes can help test scalable models and ensure that the deployment of product passports is both inclusive and effective. With aligned efforts, product passports can move from concept to cornerstone in building a circular, transparent economy underpinned by robust EPR systems.

For product passports to meaningfully support EPR, there needs to be alignment among regulatory frameworks, technological solutions, and industry adoption. Governments must embed digital passport requirements into EPR rules, while tech developers build scalable platforms. At the same time, producers must be incentivized—through tax benefits, compliance relief, or market access—to embrace these innovations.

India’s Position in the Global Shift

India’s EPR framework is rapidly advancing, especially in sectors like e-waste, plastics, and batteries. While product passports are still an emerging concept locally, pilot programs and startup innovations are beginning to take shape. If policy guidance aligns with digital infrastructure development, India could leapfrog into a leadership position by integrating traceability early into its circular economy strategy.

Looking Ahead: Building Smarter Systems for a Circular Future

As environmental regulations grow more sophisticated and public demand for sustainable practices intensifies, the integration of smarter systems into product lifecycles is no longer optional—it’s inevitable. Product passports represent a forward-thinking solution that can help close the loop on material use while supporting the broader objectives of Extended Producer Responsibility (EPR). But to fully realize this vision, stakeholders must think beyond compliance and begin investing in systems that are intelligent, adaptive, and designed for long-term circularity.

Looking ahead, we can expect to see digital infrastructure becoming more deeply embedded in product ecosystems. This includes not only the continued rollout of product passports, but also the development of integrated platforms that combine material tracking, environmental performance, supply chain data, and EPR documentation. These smart systems will be powered by technologies like blockchain for secure data exchange, artificial intelligence for lifecycle optimization, and IoT sensors for real-time updates. Together, these tools will support predictive decision-making, from eco-design to end-of-life processing.

For producers, this shift presents an opportunity to rethink value creation. Instead of simply selling products, businesses can move toward service-based models where maintenance, return, and reuse are all built-in. For governments and regulators, smarter systems mean more reliable data, better policy enforcement, and more targeted interventions. And for consumers, transparency becomes a standard feature—empowering them to make choices based on environmental and ethical considerations.

- Digital platforms that integrate EPR compliance, tracking, and reporting

- AI-driven insights to improve product design and material recovery

- Expanded use of smart labeling and IoT to enable real-time traceability

- Shift toward product-as-a-service models supporting circular use

- Public-private collaborations to scale up technology adoption

Ultimately, building smarter systems for a circular future requires a cultural and structural shift. It means prioritizing transparency, designing for longevity, and viewing waste not as a problem, but as a resource waiting to be reimagined. Product passports are a key step in that journey—linking data, accountability, and sustainability into a framework that benefits both business and the planet. Now is the time to lay the digital foundations for a system that rewards responsibility and resilience across the entire product lifecycle.

Product passports represent more than a compliance tool—they are the digital backbone of a sustainable, circular economy. As EPR policies tighten globally, embedding material traceability into products can help companies stay ahead of regulations while gaining public trust. The future of responsible production and waste recovery lies in smarter, data-driven systems, and the time to build them is now.