Unmasking the Toxic Truth Behind Modern Gadgets

In an era driven by rapid technological advancement, electronic devices have seamlessly embedded themselves into every facet of modern life. From personal gadgets like smartphones and tablets to household appliances and industrial equipment, our dependency on electronics has never been greater. Yet beneath their polished exteriors lies a troubling reality—many of these devices contain toxic substances that are invisible to the average user but pose significant risks throughout the product lifecycle.

These hazardous materials are often necessary for the function, durability, or miniaturization of electronics. However, when devices are discarded, the same substances become threats to environmental and human health. India alone generated more than 1.6 million tonnes of e-waste in 2021-22, a figure that continues to rise as digital adoption accelerates. Unfortunately, a large portion of this waste is handled in informal recycling hubs, where safety protocols are minimal or nonexistent.

Improper disposal leads to toxic leakage into the air, water, and soil, affecting not just the environment but also communities living near waste processing centers. Children working in informal recycling units are especially vulnerable, often exposed to heavy metals and chemicals without any protective gear. The health consequences—ranging from cognitive impairments to cancer—highlight the urgent need for a regulated, systemic approach to managing electronic waste.

This is where Extended Producer Responsibility (EPR) steps in. By shifting the burden of waste management from consumers and local governments to manufacturers and importers, EPR policies aim to address the hidden dangers of electronics. EPR compels companies to design products more sustainably, set up collection mechanisms, and ensure safe recycling through authorized channels. In India, the E-Waste (Management) Rules, 2022, mandate clear recycling targets for producers under an EPR framework.

- Electronics contain hazardous substances like lead, mercury, and brominated flame retardants.

- Most e-waste in India is handled by the informal sector without safety standards.

- Extended Producer Responsibility (EPR) aims to reduce harm by holding producers accountable for end-of-life management.

As electronics become more ingrained in our daily lives, understanding their environmental and health impacts becomes essential. Consumers, regulators, and producers all have roles to play in ensuring that the digital age doesn’t come at the cost of public health and ecological stability. Through awareness, regulation, and responsible innovation, we can begin to unmask—and ultimately address—the toxic truth behind our most trusted technologies.

From smartphones to smart TVs, electronics have become an integral part of our daily lives. But behind the sleek designs and cutting-edge features lies a darker reality—many of these devices contain hazardous substances that pose significant risks to both human health and the environment. This blog dives into the underbelly of electronic manufacturing, exploring how Extended Producer Responsibility (EPR) is stepping in to mitigate these dangers.

What’s Lurking Inside: Hazardous Materials in Electronics

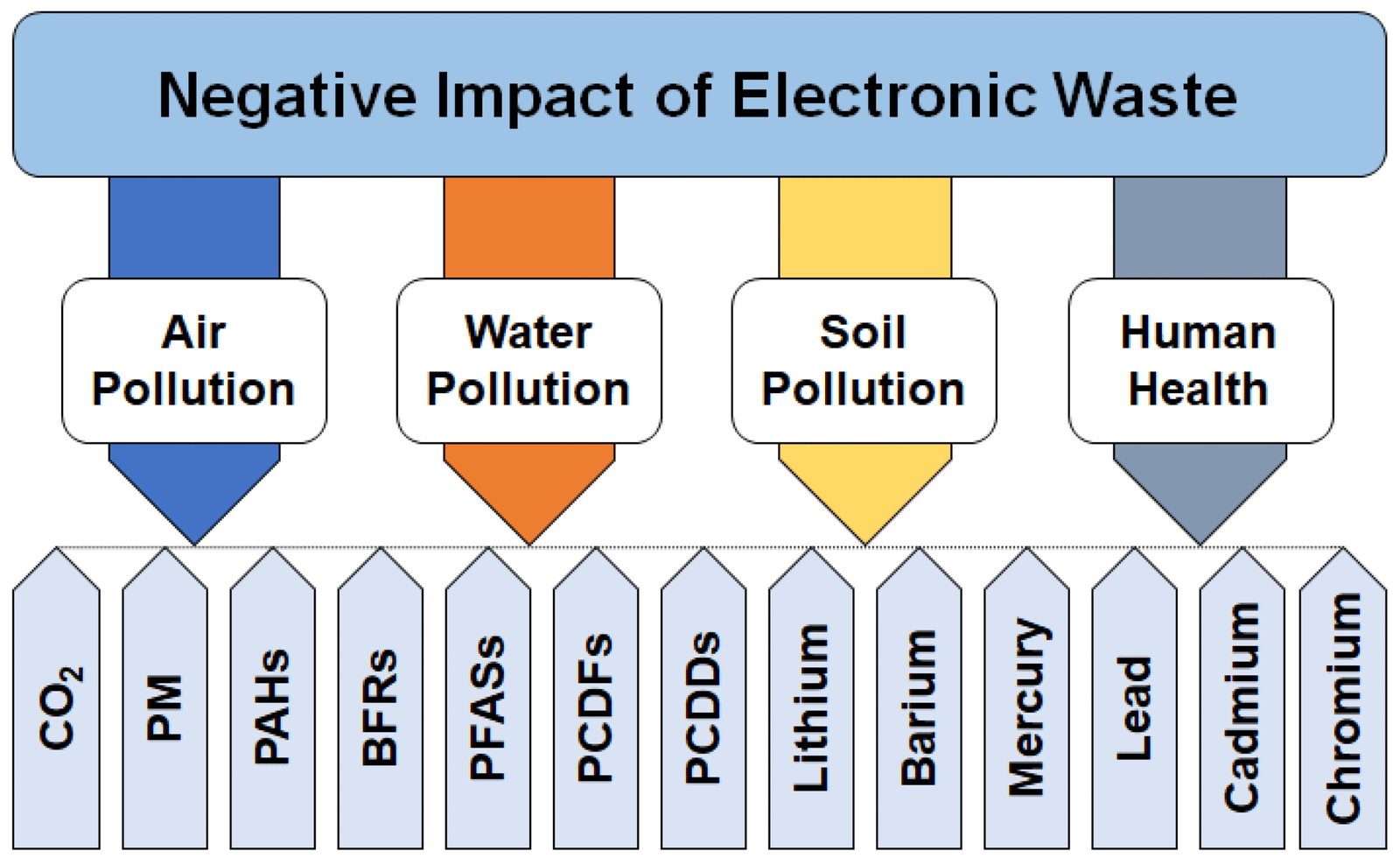

Electronic devices may seem innocuous at first glance, but their internal components often harbor a wide array of hazardous substances. These materials play critical roles in the performance and miniaturization of modern technology, yet they become serious environmental and health threats once devices reach the end of their useful life. Without proper handling, these toxic elements can leach into soil, contaminate water sources, and release harmful emissions into the air.

Most consumers are unaware of the chemical complexity embedded in their gadgets. Circuit boards, display panels, batteries, casings, and wires all contain potentially harmful elements that require specialized processing. When devices are dismantled without adequate safeguards—as is common in informal recycling sectors—these materials are released into the environment and often end up causing long-term ecological damage or entering the food chain.

- Lead – used in soldering circuit boards; causes neurological and developmental disorders.

- Mercury – found in LCD backlights and switches; highly toxic to the kidneys and nervous system.

- Cadmium – used in batteries and semiconductors; a known carcinogen that damages lungs and kidneys.

- Hexavalent chromium – used in anti-corrosion coatings; harmful to respiratory health and skin.

- Brominated flame retardants – added to plastic casings; disrupt endocrine and reproductive systems.

These substances are not only dangerous individually, but their interaction during uncontrolled burning or chemical treatments can result in the release of even more hazardous compounds, such as dioxins and furans. Informal recyclers, who often work without protective equipment, are routinely exposed to these toxicants, increasing their risk of chronic illness, respiratory problems, and cancers.

It’s important to note that many of these materials are not just hazardous—they are also valuable. Precious metals like gold, silver, palladium, and rare earth elements are embedded within e-waste and can be recovered through proper recycling techniques. However, the presence of toxic components makes the process risky unless handled by certified recyclers with access to environmentally sound technologies.

Recognizing what’s lurking inside our electronics is a critical step toward managing e-waste responsibly. Policymakers, manufacturers, and consumers must all play their part in supporting safer design, promoting regulated recycling infrastructure, and demanding accountability from the tech industry. Without this collective effort, the very devices that power our lives could end up poisoning the environment we depend on.

Electronic devices are composed of a complex cocktail of materials, some of which are toxic when not handled properly. These substances may remain safely contained during a device’s operational life but become hazardous at disposal—especially when e-waste is improperly managed.

Heavy Metals and Persistent Toxins

Heavy metals and persistent toxins are among the most concerning substances found in discarded electronics. These materials, while essential for the function of many components, pose significant environmental and health risks when not handled correctly. Lead, for instance, is commonly used in soldering circuit boards. Though effective for conductivity, it becomes hazardous when released into the environment, as it can contaminate soil and water and lead to neurological damage, especially in children.

Cadmium is another dangerous metal used in rechargeable batteries and semiconductors. It is highly toxic even in small quantities, capable of causing kidney damage and bone deterioration. Mercury, found in switches, relays, and fluorescent backlights of older LCD screens, can bioaccumulate in aquatic systems, affecting both wildlife and human populations. What makes these elements particularly troubling is their persistence—they do not degrade easily and can remain in ecosystems for decades.

In addition to heavy metals, many electronics contain brominated flame retardants (BFRs). These compounds are added to plastic casings and circuit boards to reduce flammability but are known to disrupt endocrine functions and accumulate in human tissue. When e-waste is incinerated or dismantled without proper ventilation, these substances can volatilize or leach into nearby environments, impacting air quality and public health. The long-term consequences of exposure are still being studied, but early evidence links them to developmental delays and reproductive issues.

Devices often contain heavy metals like lead, mercury, and cadmium, as well as persistent organic pollutants (POPs) such as brominated flame retardants. When dumped or incinerated, these substances can leach into soil and water or release toxic fumes, creating long-term environmental and health hazards.

Health Impacts from Exposure

Informal recycling workers and nearby communities often suffer from direct exposure. Studies have linked e-waste toxins to neurological damage, respiratory illnesses, and developmental issues in children. The lack of protective measures in many unregulated recycling hubs only worsens the problem.

How EPR Shifts the Responsibility for Safer Disposal

As the environmental and health impacts of e-waste become more evident, the need for structured accountability in electronic waste management has grown. Extended Producer Responsibility (EPR) is a regulatory mechanism that directly addresses this issue by shifting the responsibility of post-consumer waste management from the public sector to producers. Under EPR, manufacturers, importers, and brand owners are legally required to ensure that products they introduce into the market are collected, treated, and disposed of in an environmentally sound manner after their use.

In India, the E-Waste (Management) Rules, updated in 2022, operationalize EPR through mandatory targets and registration processes. Producers must submit EPR plans and meet annual collection targets based on the volume of products sold in the previous years. Non-compliance can result in penalties, and credits can be traded within the ecosystem, encouraging participation from recyclers and third-party agencies. These measures aim to create a circular economy by integrating environmental considerations into every stage of the product lifecycle.

More importantly, EPR encourages producers to design electronics with their end-of-life impact in mind. By holding manufacturers accountable for downstream consequences, it motivates the industry to invest in safer, more sustainable materials and easier-to-repair or recycle product designs. This upstream pressure is critical in reducing the presence of hazardous substances and improving recyclability.

To ensure implementation, EPR compliance is supported by digital tracking systems. India’s Central Pollution Control Board (CPCB) oversees a dedicated E-Waste Management Portal where producers must register and report progress. This platform enables traceability of e-waste from collection to recycling, helping prevent illegal dumping and promoting certified processing.

- EPR makes producers responsible for end-of-life collection and treatment of their products.

- Regulations incentivize eco-friendly design by penalizing toxic or hard-to-recycle components.

- Digital portals and reporting tools enable monitoring and reduce leakages into informal sectors.

Ultimately, EPR is more than a compliance tool—it is a catalyst for system-wide change. By integrating environmental stewardship into the business model of electronics companies, it transforms how we think about technology, consumption, and responsibility. With consistent enforcement and public awareness, EPR can significantly reduce the burden of hazardous e-waste on our ecosystems.

EPR frameworks are designed to make manufacturers accountable for the full lifecycle of their products—including their safe disposal. In the context of hazardous electronic waste, EPR not only mandates collection and recycling but also encourages cleaner design and responsible sourcing of materials.

Designing Out Toxicity

One of the most transformative impacts of Extended Producer Responsibility (EPR) lies in its ability to influence product design. By holding producers accountable for the environmental and health effects of their products even after disposal, EPR incentivizes a shift toward cleaner, safer, and more sustainable design choices. This proactive approach is commonly referred to as ‘designing out toxicity’—eliminating or minimizing the use of hazardous materials at the very start of a product’s life cycle.

For example, many electronics manufacturers are now phasing out the use of lead-based solder in favor of alternatives like tin-silver-copper alloys. Similarly, companies are reducing the use of brominated flame retardants in plastic casings and looking for halogen-free options to reduce toxic emissions during recycling or incineration. The RoHS (Restriction of Hazardous Substances) Directive in the EU has already set global benchmarks, and India’s EPR policies are beginning to encourage similar alignment. By integrating toxicity considerations into product development, companies not only simplify downstream recycling but also reduce health risks for workers and end users.

One of EPR’s biggest contributions is driving eco-design. Producers are increasingly phasing out hazardous materials in favor of safer alternatives. For instance, many companies are reducing or eliminating the use of lead solder and PVC plastics to comply with global and local regulations.

Tracking Waste Through EPR Portals

Digital compliance tools under EPR, such as India’s CPCB E-Waste Portal, help monitor the collection, transport, and processing of hazardous e-waste. This traceability ensures that harmful substances are managed through certified recycling channels and not dumped in landfills or burned.

- EPR encourages safer product design by penalizing toxic components

- It enforces compliance through traceable collection systems

- Certified recyclers handle toxic components with proper safeguards

Global Lessons: What India Can Learn from Other EPR Successes

As India continues to refine its EPR framework for electronic waste, valuable insights can be drawn from countries that have implemented successful models. Several nations across Europe and Asia have shown that well-structured EPR systems can dramatically reduce e-waste pollution, improve recycling rates, and encourage safer product design. These global examples offer not just regulatory frameworks but also practical lessons in governance, public participation, and infrastructure development.

The European Union (EU) remains one of the pioneers in EPR implementation through its Waste Electrical and Electronic Equipment (WEEE) Directive. It mandates that producers take back electronic goods, ensure proper recycling, and report volumes transparently. The success of the EU model lies not only in its stringent targets but also in its harmonized approach across member states. By creating centralized reporting systems and holding producers financially responsible, the EU has achieved some of the highest e-waste collection rates in the world—over 45% of e-waste generated is officially collected and recycled.

In Asia, Japan and South Korea offer compelling examples. Japan’s Home Appliance Recycling Law, enacted in 2001, requires consumers to return appliances to retailers, who then pass them on to certified recyclers. The system is efficient because of clear role delineation, robust collection networks, and strict enforcement. South Korea, on the other hand, uses an incentive-based system with recycling credits and strong public education campaigns that encourage citizens to participate actively in e-waste segregation.

- The EU’s WEEE Directive integrates strict compliance and traceability with producer responsibility.

- Japan mandates consumer and retailer roles in product return, ensuring a closed-loop system.

- South Korea promotes citizen engagement and incentivized recycling through credit systems.

For India, the key takeaway is that effective EPR systems require more than just regulation—they demand strong infrastructure, data transparency, and citizen awareness. Integrating lessons from global leaders can help bridge existing gaps in India’s current system, such as the dominance of informal recycling and lack of standardization in reporting. With a vast and growing e-waste stream, India stands to benefit significantly from adapting proven global practices to its local context.

Countries with mature EPR systems offer valuable lessons in hazardous substance management. The European Union’s WEEE directive, for example, has significantly curbed the environmental impact of toxic electronics through strict recycling quotas and producer take-back mandates.

Regulatory Synergy and Public Awareness

Effective EPR relies on more than just regulation—it needs informed consumers and cooperative governance. In countries like Sweden and Japan, well-publicized collection systems and consumer incentives have improved participation rates, reducing the amount of untracked hazardous e-waste.

From Toxic Legacy to Sustainable Tech Future

The unchecked growth of e-waste has created a toxic legacy that now threatens ecosystems, public health, and resource sustainability. As the volume of discarded electronics continues to climb, especially in rapidly digitizing economies like India, the need for systemic solutions becomes increasingly urgent. But this crisis also presents an opportunity—a chance to transition from a linear ‘make-use-dispose’ model to a circular economy where materials are reused, recycled, and reintegrated responsibly.

Extended Producer Responsibility (EPR) offers a strategic pathway to that future. By holding manufacturers accountable for the entire lifecycle of electronic products, EPR pushes companies to rethink product design, reduce hazardous content, and facilitate organized take-back and recycling. The shift is not only regulatory; it’s cultural. Producers are being nudged to prioritize sustainability as a core business value, and consumers are being encouraged to participate in the recycling chain through awareness and infrastructure.

Transitioning to a sustainable tech ecosystem will also require strengthening the formal recycling sector and integrating the informal workforce in safer, regulated environments. India’s recycling economy heavily depends on informal handlers who often operate without basic safety protocols. By bringing them into the fold of compliance and offering training and certification, we can protect livelihoods while ensuring environmental safety.

- EPR promotes lifecycle accountability and eco-friendly product design.

- Investment in certified recycling infrastructure can reduce environmental damage.

- Training informal workers ensures both compliance and social equity.

Looking ahead, innovation must be a cornerstone of sustainable electronics. From modular designs that allow easy repair to the use of biodegradable and non-toxic materials, the future of technology must be one where environmental impact is a design consideration—not an afterthought. Regulatory enforcement, stakeholder collaboration, and consumer behavior will all play decisive roles in turning this vision into reality.

The journey from toxic tech to sustainable systems won’t happen overnight, but the tools, frameworks, and knowledge are already in place. With consistent implementation of EPR and a commitment to responsible production and consumption, we can ensure that the next generation of electronics powers progress without poisoning the planet.

The battle against hazardous substances in electronics is far from over—but EPR offers a strong foundation for change. By shifting responsibility upstream to manufacturers, promoting safer design, and enforcing accountable recycling, EPR can help transform today’s toxic tech into tomorrow’s sustainable innovation. It’s time to rethink how we make, use, and dispose of electronics—for our health and our planet.

Leave a Reply